Chassis Fabrication for Heavy-Duty Equipment

Structural frame design requires careful consideration of load-bearing capacity, stability, and connection details in heavy-duty chassis fabrication.

What Chassis Fabrication Involves

Chassis fabrication is the process of manufacturing structural frames that carry operational loads, maintain component alignment, and provide mounting points for heavy-duty equipment.

Chassis serve as the primary load-bearing foundation and must maintain alignment under static and dynamic loads. Because chassis components support multiple downstream systems, dimensional accuracy is critical. Fabrication processes must be tightly controlled to maintain alignment and part-to-part consistency.

Design Considerations in Heavy-Duty Frame Fabrication

Effective heavy-duty frame fabrication begins with an understanding of load paths and stress distribution. Forces applied to the chassis must transfer evenly through the structure without creating localized stress concentrations that can lead to fatigue or failure.

Tolerance is another critical factor, especially in long weldments. Small deviations at individual joints can compound, affecting overall alignment and fitment. Poorly designed joints can become stress risers, especially in vibration-prone environments.

In many applications, the chassis must also account for vibration, thermal expansion, and exposure to harsh operating environments such as dirt, moisture, or temperature extremes.

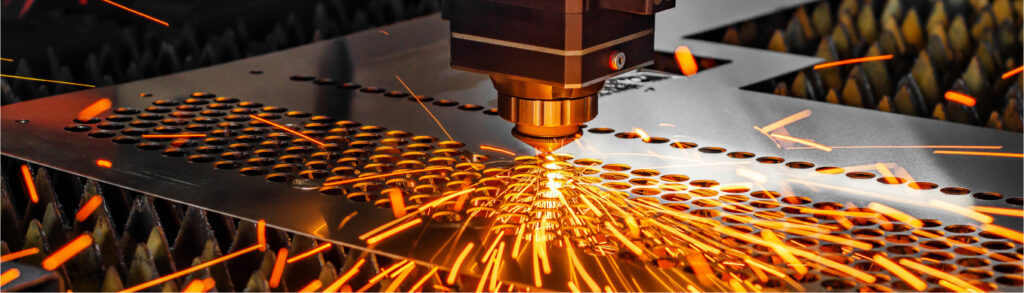

Fabrication Processes Used in Chassis Manufacturing

Chassis fabrication typically begins with laser or plasma cutting of plate materials. These processes allow for accurate part consistency prior to welding. CNC forming is often used to create brackets and bent components that add rigidity to the frame.

Welding is a core operation in chassis manufacturing. MIG welding is commonly used for structural joints, while TIG welding may be applied where tighter control or cleaner welds are required.

Common Applications for Chassis Fabrication

Fabricated chassis are used across a wide range of heavy-duty applications, including:

- Industrial vehicles and mobile equipment

- Agricultural and construction machinery

- Material handling systems

- Power generation and utility equipment

- Custom Designs

Talk to Metal

Services

you want without the headache?

design it, we can make it