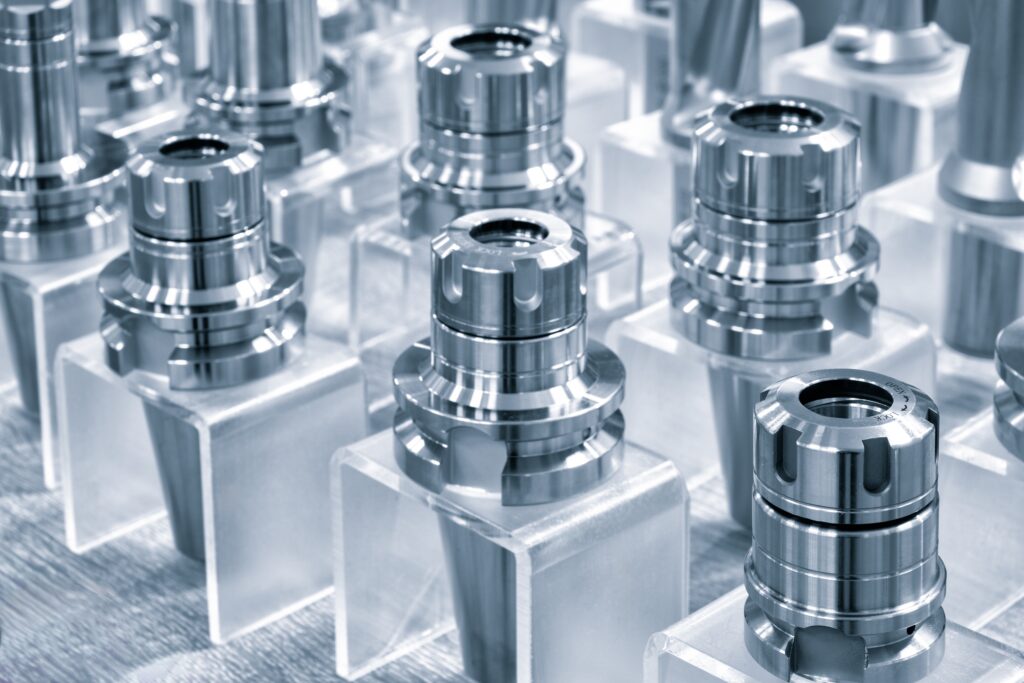

Precision in manufacturing is no longer a bonus; it’s a baseline requirement. Maintaining tight tolerances and reliable performance is critical for industries building heavy-duty machinery, large vehicles, or high-performance components. That’s where CNC machining services come in. It allows teams to meet demanding specifications with accuracy and repeatable results.

From agriculture to transportation, this method delivers parts that work right every single time.

Accuracy: CNC Machining Services Deliver High Precision

CNC machines operate using pre-programmed software, which tells them how to cut, drill, or shape a material down to thousandths of an inch. This allows them to create high-precision components, even when tolerances are tight or shapes are complex.

CNC processes are essential for industries like automotive and aerospace. Parts must fit and function in high-performance systems. These parts often need specific mechanical properties, such as impact strength, electrical insulation, or chemical resistance. Operators can adjust CNC machining services systems to maintain clean surface finishes.

Shops use CNC turning to create symmetrical parts like shafts, rods, and bushings. Combined with CNC milling, shops can deliver multi-sided, complex components with exact specifications.

How tight are typical tolerances? Modern CNC tools regularly achieve tolerances of ±0.001 inches. This level of control allows for high-quality results from materials like aluminum, stainless steel, and carbon steel. This is true even when these materials react differently to heat or pressure.

Efficiency: Fast Turnaround Without Cutting Corners

One of the biggest benefits of CNC machining services is how it streamlines the manufacturing process. Once you set up a job, it can run all the time. These cuts lead times and helps teams meet deadlines, even when there is a lot of work.

Advanced quoting tools now make it easier to start a job. With an online CNC machining services, customers can upload a 3D model and get an instant quote in minutes. This supports faster decision-making and helps move projects forward.

In-house integration of steps like laser cutting, bending, and welding also means fewer delays between operations. Shops can take on projects requiring high strength or corrosion-resistant materials and complete them under one roof. These efficiencies reduce cost, errors, and manual handling, keeping operations lean and results consistent.

You can fold even secondary operations like powder coating or plating into the workflow. This gives manufacturers the ability to deliver parts that protect against moisture absorption and environmental wear.

Consistency: Reliability Across Every Run

For industries producing thousands of parts per year or running a single prototype, repeatability matters. CNC systems allow shops to deliver the same level of accuracy over and over, from the first part to the last.

Why is this important? In applications that need replaceable parts, small differences can cause assembly problems, more waste, or performance issues.

Well-maintained machines, operator training, and digital controls all contribute to consistency. Automated feedback systems monitor tooling and make micro-adjustments during cutting. This helps ensure proper dimensions, even if the material varies slightly. With CNC technology, shops can fine-tune settings to account for those changes—supporting better mechanical properties across batches.

Even custom parts see the benefits. Engineers can tweak one program to match new sizes or design changes. They can update the design without restarting the entire process.

What makes this consistency possible? Engineers combine detailed programming, reliable tooling, and strict process control to achieve consistent results. Once they optimize the process, machines repeat it without variation. Machines operate with precision and follow the programmed instructions every time.

Reliable results. Fast turnaround. Consistent quality.

These are key reasons why CNC machining services remain central to modern manufacturing across North America.

This technology helps manufacturers stay competitive. Making short-run prototypes and fulfilling high-volume contracts is useful.

CNC machining services are becoming more critical in modern manufacturing. This is because of the growth of automation, precision in supply chains, and future innovations.

Explore how CNC machining services can support your next project.

Start a conversation with a specialist today.