Your Guide to Metal Fabrication for Agriculture Equipment

Learn ways to improve your equipment productivity, increase crop yield, and decrease costs.

Agriculture equipment like tractors and combine harvesters require perfectly fabricated parts to bring precision, accuracy, and safety to our fields, whether you’re planting seeds or working through the height of harvest season.

To get this balance of strength and precision, consider these fabrication tips and approaches as you consider the best metal fabrication materials, processes, and partner to get the best from your agriculture equipment.

Choose metal that can power through long harvest seasons

Vehicle parts can be made out of a variety of metals including aluminum, brass, carbon steel, copper, and stainless steel. But not all metals are created equal, and it takes a special kind of metal to support the kind of work performed by agriculture and field equipment.

These heavy-duty, hard-working trucks have to withstand harsh weather conditions and be able to harvest long hours and days at high speeds. Steel is often chosen for its strength and affordability, and certain types of steel offer protection against corrosion. Lightweight aluminum is considered better for fuel economy and rust prevention.

More and more, people are combining metals for a balance of durability and efficiency.

Think about the metal fabrication process as much as the metal itself

Choosing the right metal for your equipment is essential, but if the metal parts aren’t shaped correctly and properly welded to maintain the equipment’s structural integrity, it can be an ineffective, even dangerous mess.

When building equipment that will be driving over tough terrain, working through harsh environments, and regularly supporting various weight requirements from attachments and workers, you’ll want to make sure you choose a metal fabrication partner that provides precision field equipment fabrication support like:

- Advanced Welding Techniques

- CNC Machining and Laser Cutting

- Safety as a Priority in Fabrication

- Testing and Quality Assurance

Build strong equipment with equally powerful attachments

There are many things to consider when fabricating your agriculture equipment including the right type of metal (or blend of metals), additional welding services, ongoing support and repair, etc.

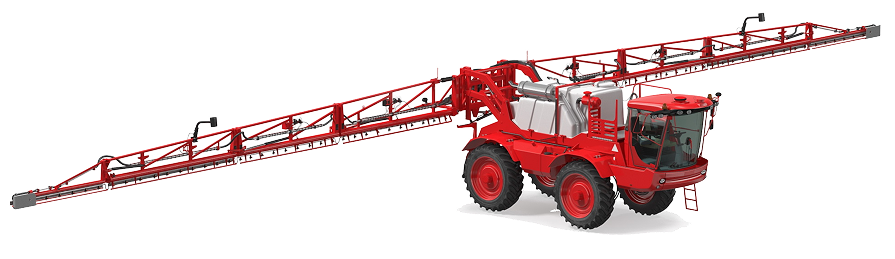

For other types of vehicles, the focus is on manufacturing the main vehicle unit, but for equipment used in fields, some attachments that are essential to perform field tasks include:

- Harvester and combine components

- Tractor attachments (mower decks, planters, spray systems)

- Tillage equipment, tanks, and silos

- Custom frames, brackets, and housings

When choosing a metal fabricator for agriculture equipment, make sure they can fabricate parts needed for the necessary attachments as well as the vehicles themselves.

Plan for speedy, accurate equipment repairs

With all the important, but extreme field work this heavy-duty equipment performs, it’s wise to plan for repairs. Not because the equipment becomes unreliable, but because harvesting the earth can bring unpredictable challenges.

Having a partner that can react quickly and thoughtfully to these challenges will make all the difference. Here are a few things to look for when requesting agriculture equipment repair services:

Speed is of the essence

Try and find a partner that will aim to turn around basic repairs within 72 hours.

On-site repairs are best

Having technicians come directly to your location eliminates the need to transport large equipment off-site and can significantly reduce downtime. And sometimes, equipment is simply too large or difficult to move.

In-house fabrication reduces downtime

Choosing an in-house fabricator solves one of the biggest repair challenges: When parts aren’t in stock. In-house fabrication also streamlines communication, which helps ensure your equipment is fixed right the first time.

Prioritize safety as much as speed

Look for companies that meet standards like AWS D1.1 for welding and ISO 9001 for quality assurance. These credentials indicate that technicians follow proven methods and safety practices.

Expect price and cost transparency

A trustworthy metal fabrication partner should offer price transparency from the beginning and make the quoting process easy.

While it’s not uncommon to need to collaborate with a partner to price out a metal fabrication job, especially custom metal fabrication requests often needed for agriculture and field equipment, be wary of quoting processes that are overly long where the price changes frequently.

Also, everyone is looking for affordable prices, but watch for metal fabricators that quote extremely low prices that could mean a lower-quality metal and fabrication process.

Ultimately, you want a partner that has a deep understanding of metal fabrication for agriculture equipment, so they can thoughtfully and quickly help you get to a price that gets you exactly what you need.

Help protect our crops with sustainable fabrication practices

Focusing on sustainability is a win-win for both the planet and the economy. People that embrace practices that promote metal utilization save money on energy, waste, and compliance with regulations. In the long run, this leads to cost savings and supports a greener industry.

And small, cost-efficient changes during the agriculture equipment fabrication process can go a long way! A few ways sustainable metal fabricators help maintain the environment include:

- Advanced techniques like laser and plasma cutting make precise cuts, leaving less unused material

- Taking scrap metal and turning it into new products

- Using innovative equipment that monitors energy usage and tweaks production methods to lower emissions

- Using nesting software that reduces product costs

Reach out to the Metal Services of Blooming Prairie team for high-quality agriculture equipment fabrication services

We help customers find innovative solutions that meet their truck metal fabrication, installation, and repair needs. If you design it, we can build it.

Connect with our team today to discuss your project.